Low Resistance Specialty Wire CuNi20 CuNi23 CuNi40 Copper Alloy Wire

Overview Low Resistance Specialty Wire CuNi20 CuNi23 CuNi40 Copper Alloy Wire Product Description Copper Nickel (CuNi) a

Send your inquiryDESCRIPTION

OverviewBasic Info.

| Resistivity | 0.5 |

| Density | 8.9 g/cm3 |

| Usages | Welding Tool |

| Emf Vs Cu (μV/ 0c) (0~100 0c) | -43 |

| Melting Point | 1200c |

| TCR X10-6 / 0c (20~600 0c) | <-6 |

| Surface | Bright |

| Certificate | RoHS |

| Condition | Soft Annealed |

| Treatment | Hydrogen Annealing |

| Technique | Cold Drawing |

| Transport Package | Carton or Wooden Case |

| Specification | 0.01mm-10mm |

| Trademark | DLX |

| Origin | Changzhou, Jiangsu, China |

| HS Code | 7506100000 |

| Production Capacity | 1000kg Per Week |

Product Description

Low Resistance Specialty Wire CuNi20 CuNi23 CuNi40 Copper Alloy Wire

Product Description

Copper Nickel (CuNi) alloys are medium to low resistance materials typically used in applications with maximum operating temperatures up to 600°C (1,110°F).

With low temperature coefficients of electrical resistance, resistance, and thus performance, is consistent regardless oftemperature. Copper Nickel alloys mechanically boast good ductility, are easily soldered and welded, as well as have outstanding corrosion resistance. These alloys are typically used in high current applications requiring a high level of precision.

Constantan Wire with moderate resistivity and low temperature coefficent of resistance with a flat resistance/temperature curve over a wider range than the "manganins". Constantan also shows better corrosion resistance than the man ganins. Uses tend to be restricted to ac circuits.

Constantan wire is also the negative element of the type J thermocouple with Iron being the positive; type J thermocouples are used in heat treating applications. Also, it is the negative element of the type T thermocouple with OFHC Copper the positive; type T thermocouples are used at cryogenic temperatures.

Copper Nickel Resistance Alloys

Copper Nickel (CuNi) alloys are medium to low resistance materials typically used in applications with maximum operating temperatures up to 400°C (750°F).

With low temperature coefficients of electrical resistance, resistance, and thus performance, is consistent regardless of temperature. Copper Nickel alloys mechanically boast good ductility, are easily soldered and welded, as well as have outstanding corrosion resistance. These alloys are typically used in high current applications requiring a high level of precision.

Type | Electrical resistivity (20degreeΩ mm²/m) | temperature coefficient of resistance (10^6/degree) | Density g/mm² | Max. temperature (°c) | Melting point (°c) |

CuNi1 | 0.03 | <1000 | 8.9 | 200 | 1085 |

CuNi2 | 0.05 | <1200 | 8.9 | 200 | 1090 |

CuNi6 | 0.10 | <600 | 8.9 | 220 | 1095 |

CuNi8 | 0.12 | <570 | 8.9 | 250 | 1097 |

CuNi10 | 0.15 | <500 | 8.9 | 250 | 1100 |

CuNi14 | 0.20 | <380 | 8.9 | 300 | 1115 |

CuNi19 | 0.25 | <250 | 8.9 | 300 | 1135 |

CuNi23 | 0.30 | <160 | 8.9 | 300 | 1150 |

CuNi30 | 0.35 | <100 | 8.9 | 350 | 1170 |

CuNi34 | 0.40 | -0 | 8.9 | 350 | 1180 |

CuNi40 | 0.48 | ±40 | 8.9 | 400 | 1280 |

CuNi44 | 0.49 | <-6 | 8.9 | 400 | 1280 |

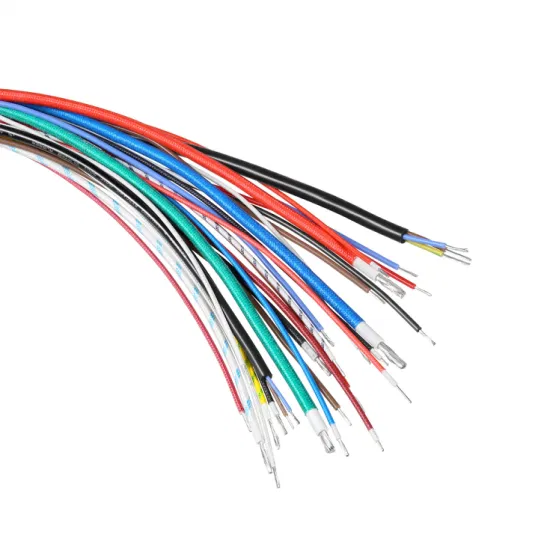

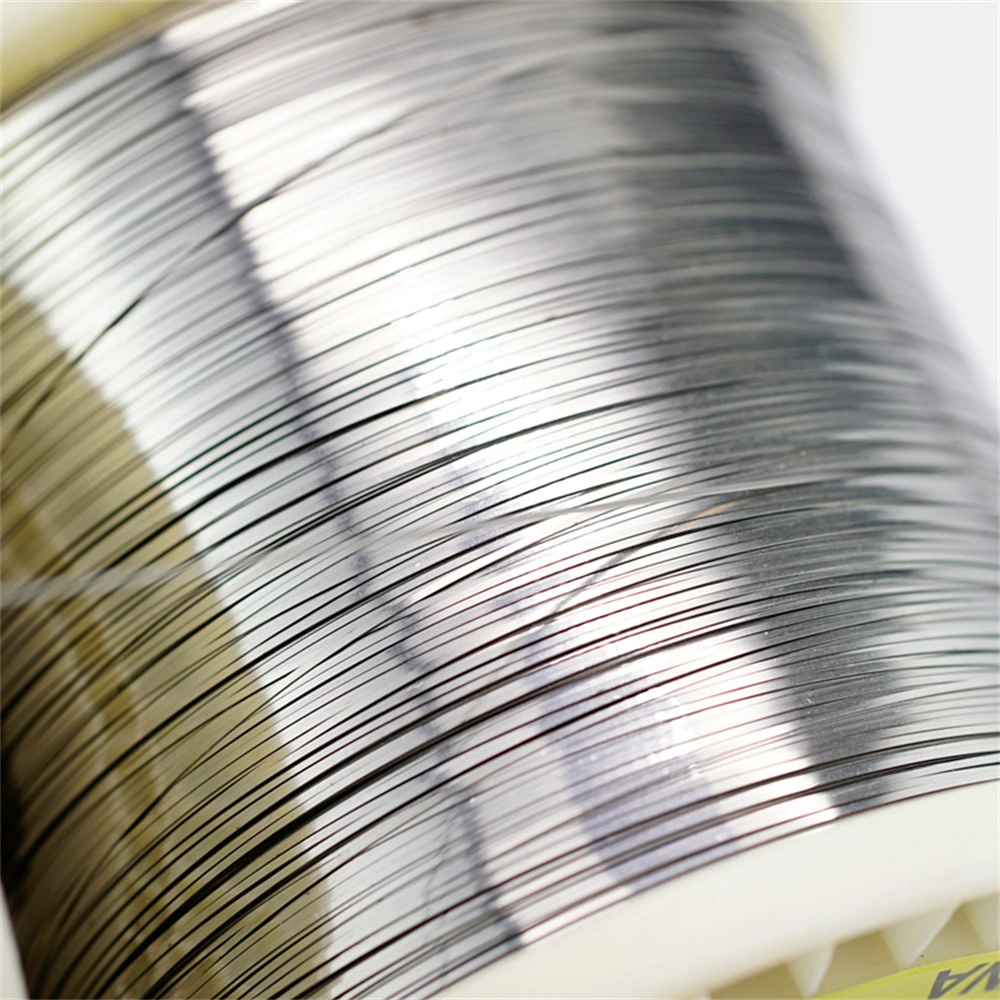

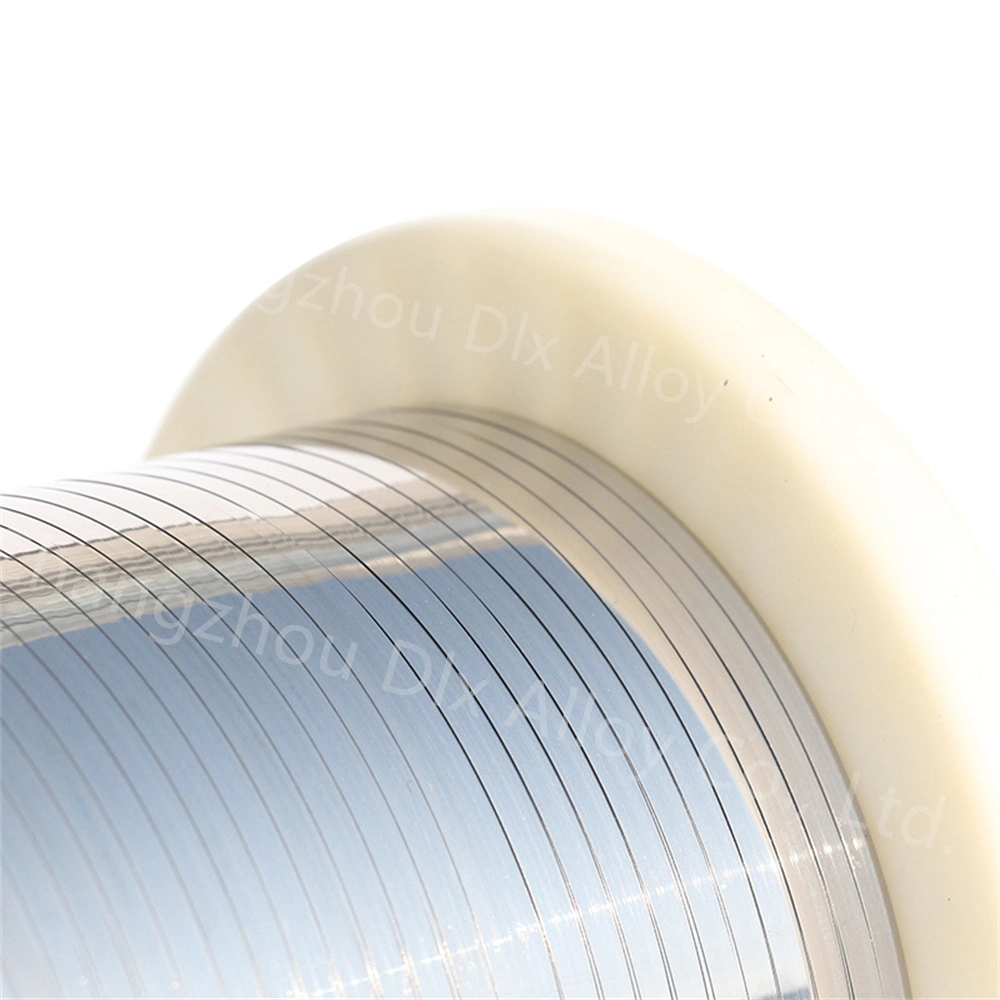

Detailed Photos

Certifications

Company Profile

Our company Principle is " Quality first, Customer first".

CHANGZHOU DLX ALLOY CO, LTD was established in 2002 and has got Iso9001 International Quality Management System Certificate and SGS Certificate. Our factory is professional in researching and producing special alloy material. From melting, drawing, heat treatment, finishing and testing .We offer nickel-based, copper-based, and iron-based alloys, including super alloy, welding materials, anti-corrosion alloy, precision alloy, FeCrAl alloy, NiCr alloy, CuNi alloy, thermocouple and etc, in the form of wire, strip, ribbon, bar, tube, plate.

1, We're able to design and develop the product what our customers require and meet their requirements through providing the appropriate engineering drawings or samples.2, We can provide the products within a week after payment.3, Wecan provide sample of the products customer need.4, We always insist on "Quality first, Customer first" as our business philosophy.

Packaging & Shipping

Question: Are you a trading company or manufacturer?

Answer: We're manufacturer.

Question: could we visit your factory?Answer: Sure, factory visit is warmly welcome.